Manufacturing

Find the best fit CNC machining service for your plastic and metal parts, which produce and deliver on-demand.

Manufacturing

Qualimount’s precision machine shop is dedicated to producing high-quality precision machined parts that meet and exceed your expectations.

- Tolerance as tight as ±0.01 mm

- 100% part inspection

- 24/7 Engineering support

Made to order from 1 to 10,000 pieces on demand

One-on-one support service, Response within 12 hours

In-house machine shop, 24/7 operations, Quick turnaround

Tight tolerance ±0.05mm, Surface roughness Ra0.2μm

ISO 9001:2015 certified, 100% part inspection

CNC

What We Good At CNC Machining Processes

CNC Milling

Qualimount offers custom CNC milling services for plastic and metal parts. With our multi-axis CNC machining centres, we can produce a variety of simple and complex CNC milled parts. Whether you need prototypes or product parts, our experienced teams can provide them with high standards and cost-effectiveness. We also have many surface finish options so that your machined part is exactly what you need it to be.

Qualimount has 3-axis, 4-axis, and 5-axis CNC milling capabilities. 3-axis and 4-axis CNC machines operate on the X, Y, and Z axes, which are the most commonly used CNC milling process. They are often applied to produce parts with relatively simple geometry. 5-axis CNC machines are the high standard and advanced type of CNC mill, which represents the manufacturing capabilities of custom CNC milling. With this mill, we can machine 5 sides of a work piece with one machine without multiple setups. Compared with 3-axis CNC milling, it is significantly more efficient and can be created geometrically complex parts with high accuracy.

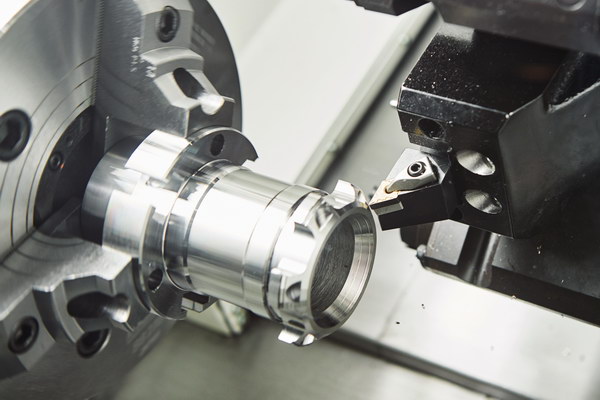

CNC Turning

The process range of CNC turning is very wide, which can be processed various types of rotary surfaces, such as external turning, internal turning, taper turning, parting, facing, boring, reaming, drilling, knurling, threading, grooving, etc.

Our CNC lathes can provide efficient boring operations with live tooling. Mount the boring head with one, two, or multiple cutters into the tailstock or the rotates head and process deep or large diameter holes with the same precision and rigidity parameters. It saves your time and the precision of the turning parts is higher. Turn-mill lathes allow for multiple processes and multi-step machining operations on a single machine, making them a cost-effective option for complex geometries.

CNC turned parts can be made from an exceptionally wide range of metal and plastic materials. For example, metals include aluminium, steel, stainless steel, brass, copper, magnesium alloy, titanium alloy, etc., as well as plastics ABS, POM, PEEK, acrylic, nylon, etc.

Qualimount

Finishing Services From Certified Suppliers

CNC

Common Post Processing

Sanding and Polishing

Smooth sanding can remove machining marks, burrs, machine lines, and adhesive marks on the surface of the parts. The flatness of the part will be improved and roughness will be reduced to create a smooth and uniform look.

High polishing process is used for a mirror finish on normal plastic, metal parts, and clear acrylic and polycarbonate parts, to achieve a precise uniform flat surface and professional-grade gloss, or to enhance the optical clarity of clear parts.

- Sanded to 600 grit sandpaper surface finish is Ra 0.8 μm;

- Sanded to 1000 grit sandpaper surface finish is Ra 0.4 μm;

- Mirror polished and clear polished surface finish is Ra 0.1-0.05 μm.

Hand Finishing

From de-flashing to gluing, filling, modifying, adding inserts, pre-fitting, measuring, and assembling, our handcraft specialists focus on every engineering detail and design specification.All post-processing is created in-house, but our team can also work with client-supplied components to finish and assemble as needed, include mating and fitting parts. Normally, this reveals engineering hurdles that are not apparent in CAD design. We will help overcome these challenges, offer solutions and achieve a finished project.

Machined Finish

Machined parts will have marks that follow the path of the cutting tool. The machined finish is that a smooth surface, created by a machine without polishing work, only needs a little handwork to clear the bur, the part could be finished and delivered quickly soon after off the machine.

- The standard machined surface roughness is Ra 3.2-1.6 μm;

- The smooth machined surface roughness is Ra 1.6-0.8 μm;

- The super-finished surface roughness is Ra 0.8-0.2 μm.

- The finishing will increase the cost of producing a part, as extra machining steps and tighter quality control are required.

Blasting

Bead blasting adds a uniform matte surface finish on a machined part, removing the marks of tool and sandpaper. It is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, or remove surface contaminants. The size of the air pressure and the size of the glass beads are the main process parameters. Glass beads come in different sizes from #80 to #220.

Finishing

Finishing Services Options

Anodizing

Anodizing helps to resist corrosion, increase surface hardness, improve resistance to wear. This process serves both functional and cosmetic purposes. There are two main types of anodizing:

Type II anodizing is mainly used to produce parts with a uniform, aesthetically pleasing surface and provides good corrosion and limited wear resistance, and has a wide variety of color dye options. The typical coating thickness: 12-18 μm for black, 8-12 μm for clear, 4-8 μm for color.

Type III anodizing also known as hard anodizing, provides excellent corrosion and wear resistance, suitable for functional applications, but is more limited in color—often clear or black only. The typical thickness 30-125 μm.

Powder Coating

Powder coating adds a thin layer of protective polymer on the surface of the part. It uses corona discharge phenomenon to make powder coating adsorbed on the workpiece, which is a strong, wear-resistant finish. The typical thickness varies from approximately 50 μm up to 150 μm.

Printing & Etching

You can print custom text and logos on the parts. Silk screening can be used for larger surfaces and when mixing multiple colors for even more complex graphics; Pad printing can be used for printing on curved surfaces; Laser etching is ideal for making precise and permanent marks on metal and and some plastics.

Qualimount

Quality Inspection Equipment

- Carl Zeiss CMM 1000×1200×600

- Granite Inspection Table, 1200×1000 (mm) / 1000×750 (mm)

- Digimatic Heitht Gages, 0-600 (mm)

- Full Range of Vernier Caliper, 0-100-150-200-300-600-1000 (mm)

- Outside Micrometers / Digimatic Holtest, 0-25-75-100-125-150 (mm) / 12-20-50-100 (mm)

- Full Range of Pin Gage / Gage Block, 0.5-12 (mm) / 1.0-100 (mm), Step 0.01mm

- Surface Roughness Tester, Hardness Tester, etc.